Chapter 1: Introduction to DFMA

The History of DFMA

Review the DFMA timeline below to become familiar with the most significant milestones leading to the development and use of DFMA in engineering practices. Select the arrow on the right side of the interactive timeline to progress through the decades. You can also select the icon in the upper right corner to expand your view.

So, what is DFMA?

Design for Manufacture and Assembly (DFMA) is an engineering methodology which focuses on reducing time-to-market and total production costs by prioritizing the following during the early design phases of the product life cycle.

- Ease of manufacture for the product’s parts.

- Simplified assembly of those parts into the final product

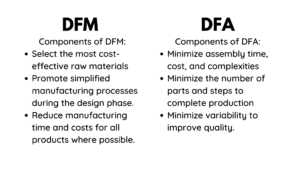

DFMA is comprised of two components: Design for Manufacturing (DFM) and Design for Assembly (DFA).

The goal is to design a product which makes the customer happy and is the lowest overall cost, but there are other factors as well:

- Best material for the process and product

- Minimum number of components

- Easy to acquire to the components

- Easy to assemble

- Easy to maintain the device

- Easy to recycle at the end of the product’s life

The product starts and ends with the customer. It could be called the voice of the customer, stakeholder input/analysis, customer request, scope of work, or critical quality requirements. Learn more about how to manufacture success by reviewing the following plan by David M. Vranson: A Plan for Manufacturing Success (2011)

References

Boothroyd Dewhurst, Inc. (2018). What is DFMA? [Video]. YouTube. https://www.youtube.com/watch?v=H6XtXCvhaec

Boothroyd Dewhurst, Inc. (2010). Case study: Desgin in cost reduction. Quality Magazine. Retrieved on May 8, 2023 from https://www.qualitymag.com/articles/84738-case-study-design-in-cost-reduction

DFMA (2023). How do you reduce cost while still achieving function, reliability, and time to market objectives? Retrieved on May 8, 2023 from https://www.dfma.com/

Dong, D., Zou, Y., Pan, H., Zhou, G., Feng, Y., & Tang, Y. (2023). DFMA-oriented modular and parametric design and secondary splitting of vertical PC components. Scientific Reports, 13. https://doi.org/10.1038/s41598-023-30192-z

Favi, C., Mandolini, M., Campi, F., Cicconi, P., Raffaeli, R., & Germani, M. (2021). Design for manufacturing and assembly: A method for rules classification. Advanances on Mechanics, Design Engineering, and Manufacturing III. https://doi.org/10.1007/978-3-030-70566-4_56

Formentini, G., Rodriguez, N., & Favi, C. (2022). Design for manufacturing and assembly methods in the product development process of mechanical products: A systematic literature review. The International Journal of Advanced Manufacturing Technology, 120. https://doi.org./10.1007/s00170-022-08837-6

Goldense, B. (2022). A history of design for manufacturing and assembly. MachineDesign. Retrieved on June 23, 2023 from https://www.machinedesign.com/automation-iiot/article/21213546/a-history-of-design-for-manufacturing-and-assembly

Liu, H., Zhang, Y., Lei, Z., Li, H., Han, S. (2021). Design for manufacturing and assembly: A BIM-Enabled generated framework for building panelization design. Smart Manufacturing for Industrialized Construction. https://doi.org/10.1155/2021/555455

Maverick, J. (2023). Is it more important for a company to lower costs or increase revenue? Investopedia. Retrieved on May 8, 2023 from https://www.investopedia.com/ask/answers/122214/company-it-more-important-lower-costs-or-increase-revenue.asp

de Oliveira, S., dos Santos, M., Kieling, A. (2021). The integration of DFMA and reverse engineering applied to a landing gear redesign. Journal of Engineering and Technology for Industrial Applications, 7(31). https://doi.org/10.5935/jetia.v7i31.775

Roxas, C., Bautistia, C., Cruz, O., Dela Crus, R., De Pedro, J., Bungca, J., Lejano, B., & Ongpeng, J. (2023). Design for manufacturing and assembly and design for deconstruction in the construction industry: Challenges, trends, and developments. Buildings, 13(5). https://doi.org/10.3390/buildings13051164

Siemens (2023). Design for manufacturing and assembly. Retrieved on May 8, 2023 from https://www.plm.automation.siemens.com/global/en/our-story/glossary/design-for-manufacturing-and-assembly-dfma/53982